Research and present occupational hazards in one major industry from home country (India),

Textile industry, (literature search, hazard identification, industry mapping).

1. Dr.Turusbekova Akshoola Kozmanbetovna

2. Tushar Jain

(Teacher, International Medical Faculty, Osh State University, Kyrgyzstan

Student, International Medical Faculty, Osh State University, Kyrgyzstan)

Abstract

The textile industry in India is a major economic driver, providing employment to over 45 million people. However, workers across the value chain face diverse occupational hazards, including respiratory diseases from fiber dust, chemical toxicity in processing, excessive noise, and musculoskeletal disorders from poor ergonomics. This report maps these hazards across regional clusters, analyzes the clinical pathogenesis of diseases like byssinosis, and evaluates the impact of recent regulatory reforms such as the Occupational Safety, Health and Working Conditions (OSH) Code 2020. Findings indicate that while fatal accidents are stabilizing, non-formal workers remain highly vulnerable to chronic health degradation.

Keywords: Occupational Health and Safety (OHS), Indian Textile Industry, Byssinosis, Noise-Induced Hearing Loss (NIHL), Musculoskeletal Disorders (MSDs), OSH Code 2020.

The textile industry in India serves as a critical pillar of the national economy, embodying a complex "Farm to Fibre to Factory to Fashion to Foreign" value chain that sustains millions of livelihoods. As the second-largest employer in the country after agriculture, the sector provides direct employment to over 45 million people, including approximately 3.5 million handloom workers, and contributes roughly 2.3% to the national Gross Domestic Product (GDP), 13% to industrial production, and 12% to total export earnings.1 Despite this economic vibrancy, the industry’s fragmented structure—ranging from traditional handlooms and powerlooms to modern, vertically integrated mills—presents a diverse and daunting array of occupational hazards.2 The transition from colonial-era regulations like the Factories Act of 1948 to the modernized Occupational Safety, Health and Working Conditions (OSH) Code of 2020 reflects a growing recognition of the need to address these hazards within a unified, investment-ready labor market.3

Industry Mapping and the Geographic Distribution of Risk

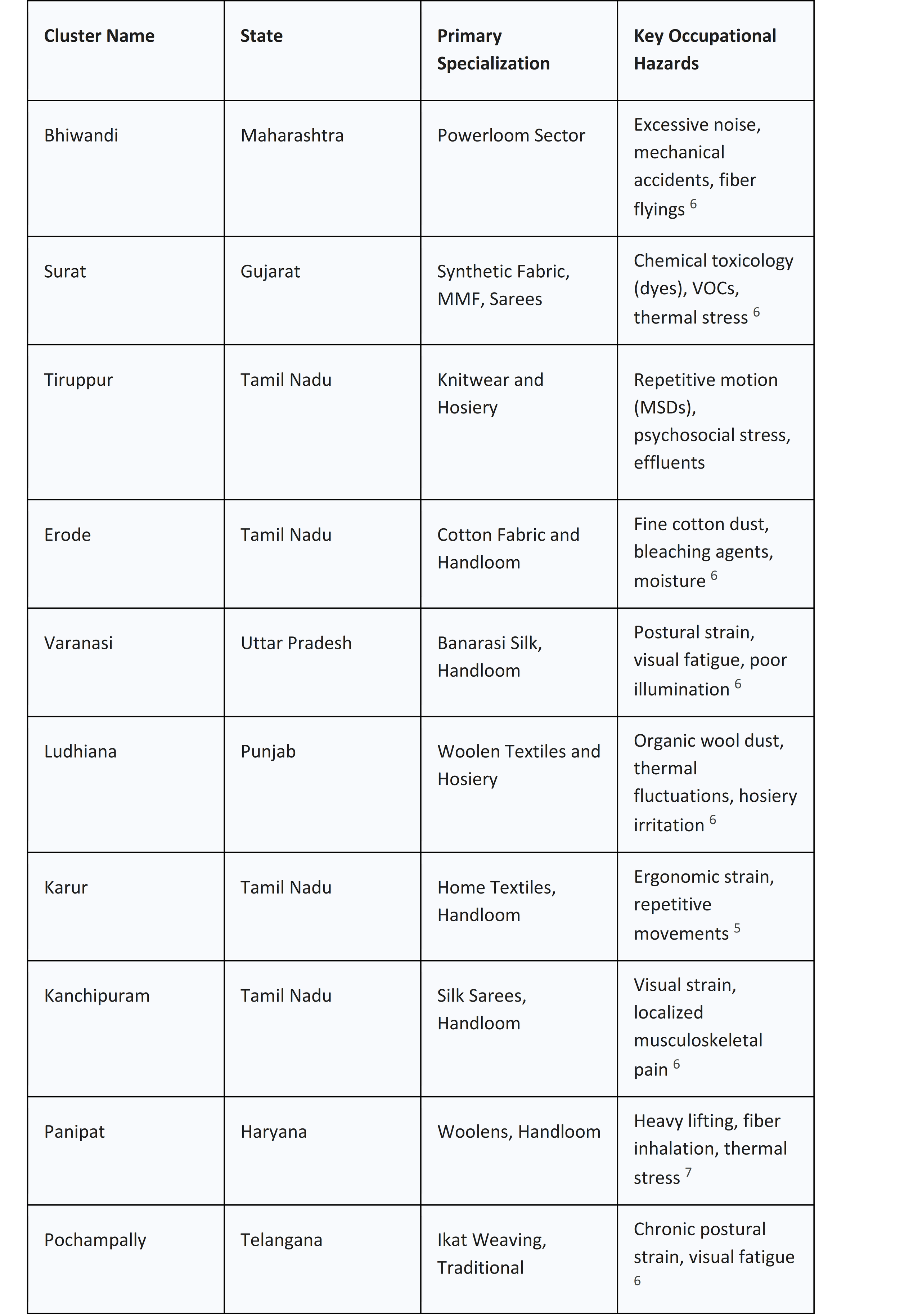

India's textile landscape is characterized by distinct regional clusters, each possessing specialized capabilities that collectively strengthen the national value chain while concentrating specific occupational risks.5 These clusters are often categorized by their primary segment—spinning, weaving, or processing—and their geographic location dictates the prevailing socio-economic conditions and environmental stressors faced by workers.

Regional Specialization and Segmental Hazards

The strategic distribution of textile clusters across the Central, Southern, Northern, and Eastern zones of India creates a localized risk profile for workers.1 For instance, the Central Zone, comprising Gujarat and Maharashtra, dominates cotton production and synthetic fabric manufacturing, leading to high exposures to organic dust and toxic chemical dyes.5

The industry’s vertical integration, while boosting competitiveness, creates a situation where a single worker or community may be exposed to multiple stages of the value chain simultaneously, particularly in informal cottage industries.5 The emergence of technical textiles—spanning twelve categories such as Agrotech, Meditech, and Protech—further diversifies the hazard landscape by introducing high-tenacity synthetic fibers like Nomex, Kevlar, and Spandex, which require specialized chemical treatments and physical handling.8

Infrastructure Evolution: PM MITRA and Mega Parks

To address the fragmentation and logistics costs that hamper the industry, the Government of India has approved the creation of seven PM Mega Integrated Textile Region and Apparel (PM MITRA) parks across Tamil Nadu, Telangana, Gujarat, Karnataka, Madhya Pradesh, Uttar Pradesh, and Maharashtra. These parks aim to create an integrated ecosystem that adheres to global sustainability and safety standards, potentially reducing the haphazard exposure risks found in older, congested clusters.9 By concentrating production within world-class infrastructure, the government seeks to foster a safety culture that is often absent in micro-units.

Respiratory Hazards: Pathophysiology and Pathogenesis of Fibre Dust

Respiratory ailments constitute the most pervasive class of occupational diseases in the Indian textile sector, with byssinosis, or "brown lung disease," serving as the most significant clinical concern.2 This condition is primarily associated with the inhalation of raw cotton, flax, hemp, or jute dust during the manufacturing process.10

Byssinosis and the "Monday Fever" Phenomenon

Byssinosis is characterized by a unique temporal pattern of symptoms, often colloquially termed "Monday Fever" or "mill fever".12 Workers frequently report chest tightness, coughing, and dyspnea that are most acute on the first day of the workweek after a period of rest, with symptoms typically diminishing as the week progresses.12 Chronic exposure, however, leads to persistent respiratory impairment, including chronic bronchitis, lung fibrosis, and eventually end-stage lung disease or respiratory failure.12

The underlying pathophysiology is increasingly linked to the presence of endotoxins—lipopolysaccharides found in the cell walls of Gram-negative bacteria that colonize raw cotton fibers.12 When these endotoxins are inhaled, they provoke an inflammatory response, triggering the release of nitric oxide and superoxide, which leads to airway narrowing and subsequent fibrosis.12 In Indian textile workers, the prevalence of byssinosis has been documented at levels between 28% and 47%, reflecting a significant burden of occupational morbidity.15

Comparative Dust Density and Exposure Thresholds

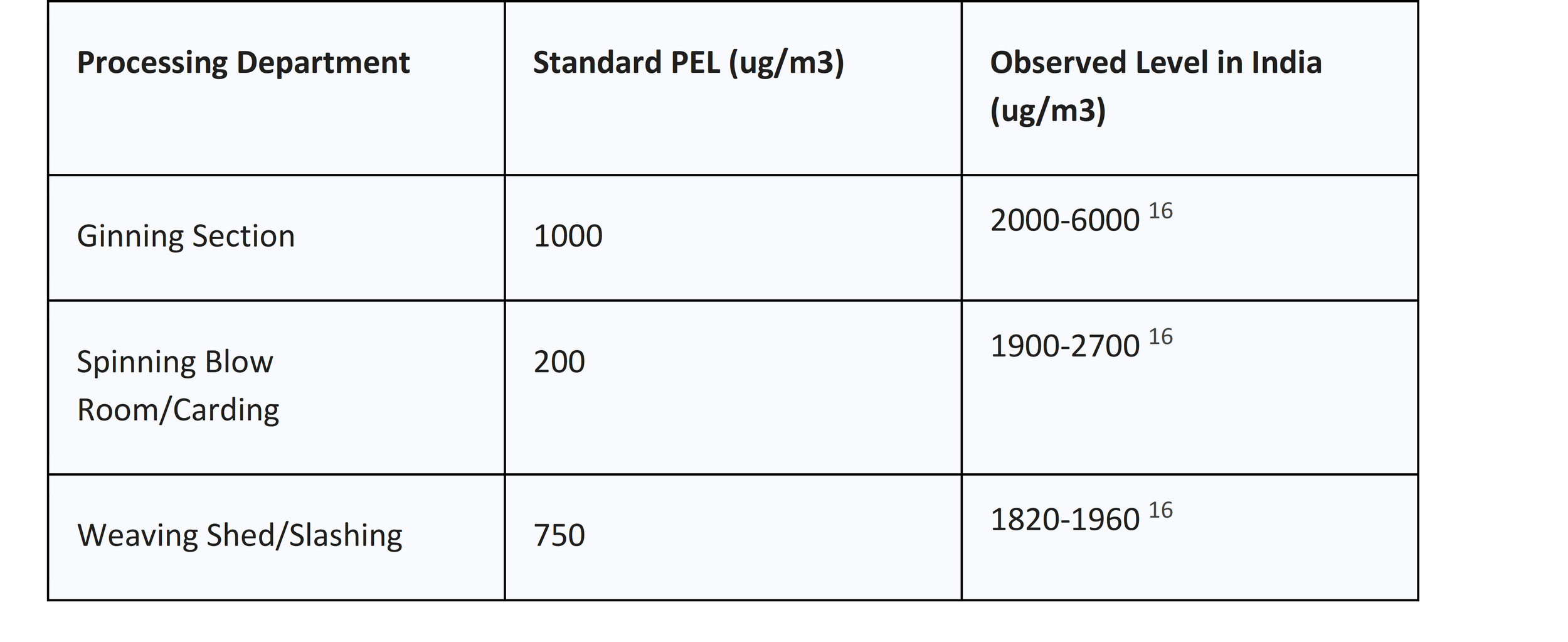

The concentrations of airborne cotton dust in Indian facilities often dramatically exceed both national and international permissible exposure limits (PEL).16

The actual density of cotton dust in spinning rooms is found to be 10 to 14 times higher than the permissible limits, a disparity that is further exacerbated by the lack of adequate ventilation and humidity control in many units.16 While NIOSH recommendations suggest a limit of 0.2 mg/m3 (200 ug/m3) for all raw cotton dust exposures, Indian workers in ginning and weaving are routinely exposed to levels that cause immediate and long-term pulmonary tissue damage.17 Recent studies in Tirupur have confirmed poor pulmonary function in workers with significant drops in FEV1 and FVC ratios.

Toxicological Hazards: Chemical Exposure in Dyeing and Finishing

The processing segment, encompassing dyeing, bleaching, and finishing, is widely regarded as the most hazardous stage of textile manufacturing due to the intensive use of toxic, mutagenic, and carcinogenic chemicals.18 This stage utilizes a vast array of substances, from aromatic amines to heavy metals and formaldehyde-based resins.19

Carcinogenic Aromatic Amines and Azo Dyes

Azo dyes are the most common synthetic colorants in the industry.20 A significant subset of these dyes can undergo reductive cleavage to release aromatic amines, many of which are known human carcinogens.18

● Banned Amines: India has published legislation prohibiting the handling of 112 azo- and benzidine-based dyes.21 These substances, such as 2-naphthylamine and benzidine, are associated with an increased risk of bladder and lung cancer.18

● Mechanism of Exposure: Exposure occurs not only through inhalation but also through ingestion and dermal absorption, particularly when sweating causes dyes to migrate from the fabric into the skin.18

● Reactive and Mineral Dyes: Reactive dyes can cause respiratory sensitization, leading to occupational asthma, while mineral dyes often contain heavy metals like chromium and lead, which can damage DNA and block enzyme activity.18

Bleaching Agents and Gaseous Irritants

Bleaching processes utilize aggressive oxidizing agents that present immediate inhalation risks.18

● Chlorine and Chlorine Dioxide: Used for removing discoloration, these gases irritate the respiratory system and nose. Chronic exposure is linked to a significant disturbance in smell function, with workers exposed to chlorine suffering 6.33 times more than non-exposed individuals.20

● Formaldehyde: This substance is frequently used in finishing to make fabrics wrinkle-free and waterproof. It is a recognized carcinogen and can cause dizziness, headaches, and chronic eczema.20

● Hydrogen Sulfide (H2S): Released during viscose rayon manufacturing, H2S is highly toxic and can be lethal at concentrations of 1000-2000 ppm. At lower levels, it is known for its "rotten egg" odor, but at hazardous concentrations, it causes smell paralysis, making it a "silent" killer.20

Physical Hazards: Noise, Mechanical Trauma, and Thermal Stress

The mechanical environment of a textile mill is characterized by high-speed rotary parts, intense noise, and significant thermal loads.22

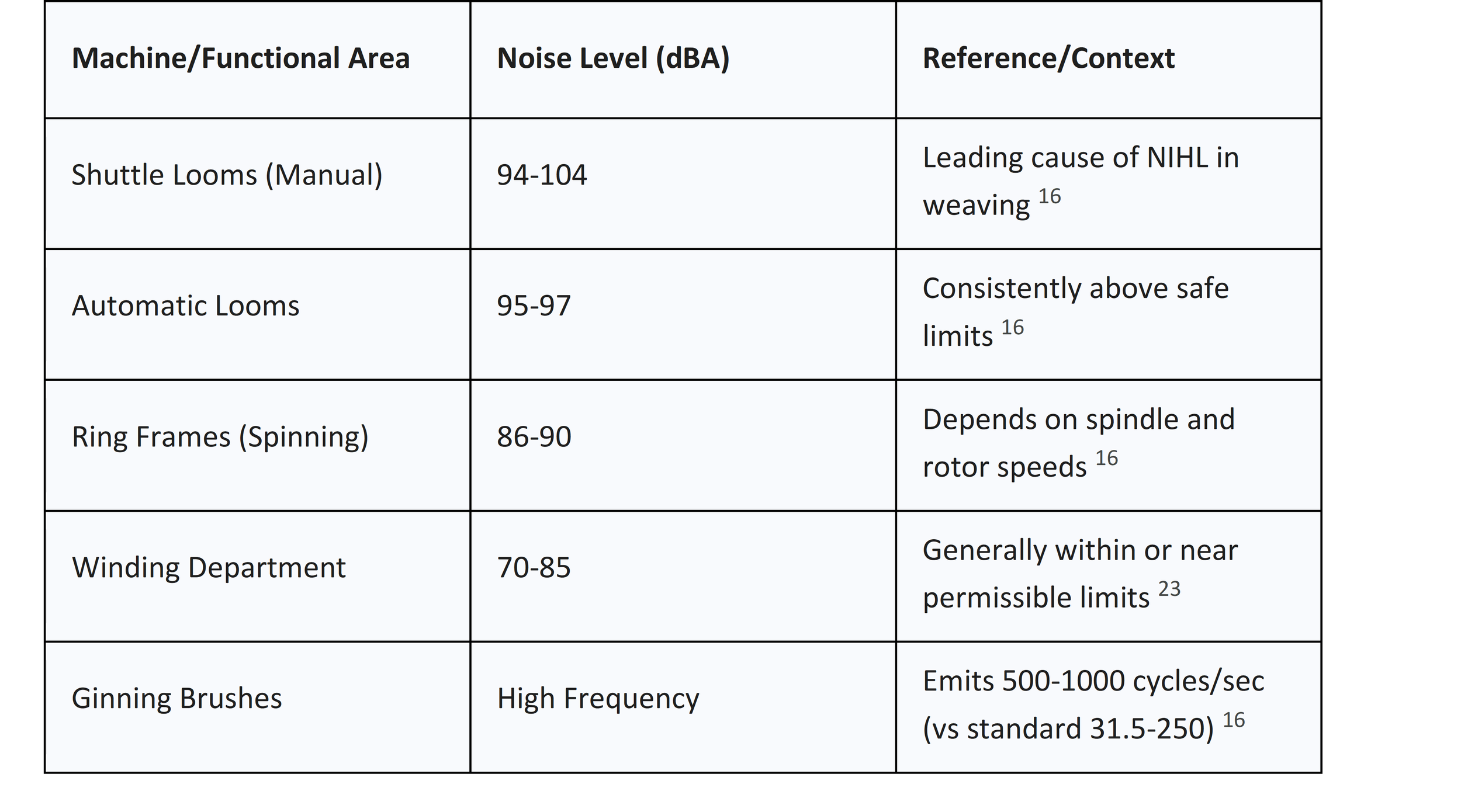

Acoustic Hazards and Noise-Induced Hearing Loss

Noise is an omnipresent hazard, particularly in ginning and weaving. The use of outdated machinery and high-density loom configurations generates noise levels that consistently exceed the 90 dBA permissible threshold for an 8-hour shift.16

Exposure to noise exceeding 80-85 dBA is linked to both auditory damage (permanent hearing loss) and non-auditory effects such as increased pulse rate, hypertension, and reduced cognitive efficiency.16

Mechanical Accidents and Fire Safety

Mechanical hazards are predominantly caused by unguarded moving parts and improper material handling.25

● Injury Patterns: The highest number of injuries occurs in the hands and fingers, followed by the back, spine, eyes, and feet.24 These accidents are often the result of flying metal chips or getting caught in machinery.25

● Fire and Explosions: The presence of combustible fiber flyings, lint, and flammable solvents creates a persistent fire risk.25 Reducing agents like sodium hydrosulphite can generate heat when contaminated with water, potentially leading to spontaneous ignition.18

Ergonomic Hazards and Musculoskeletal Disorders (MSDs)

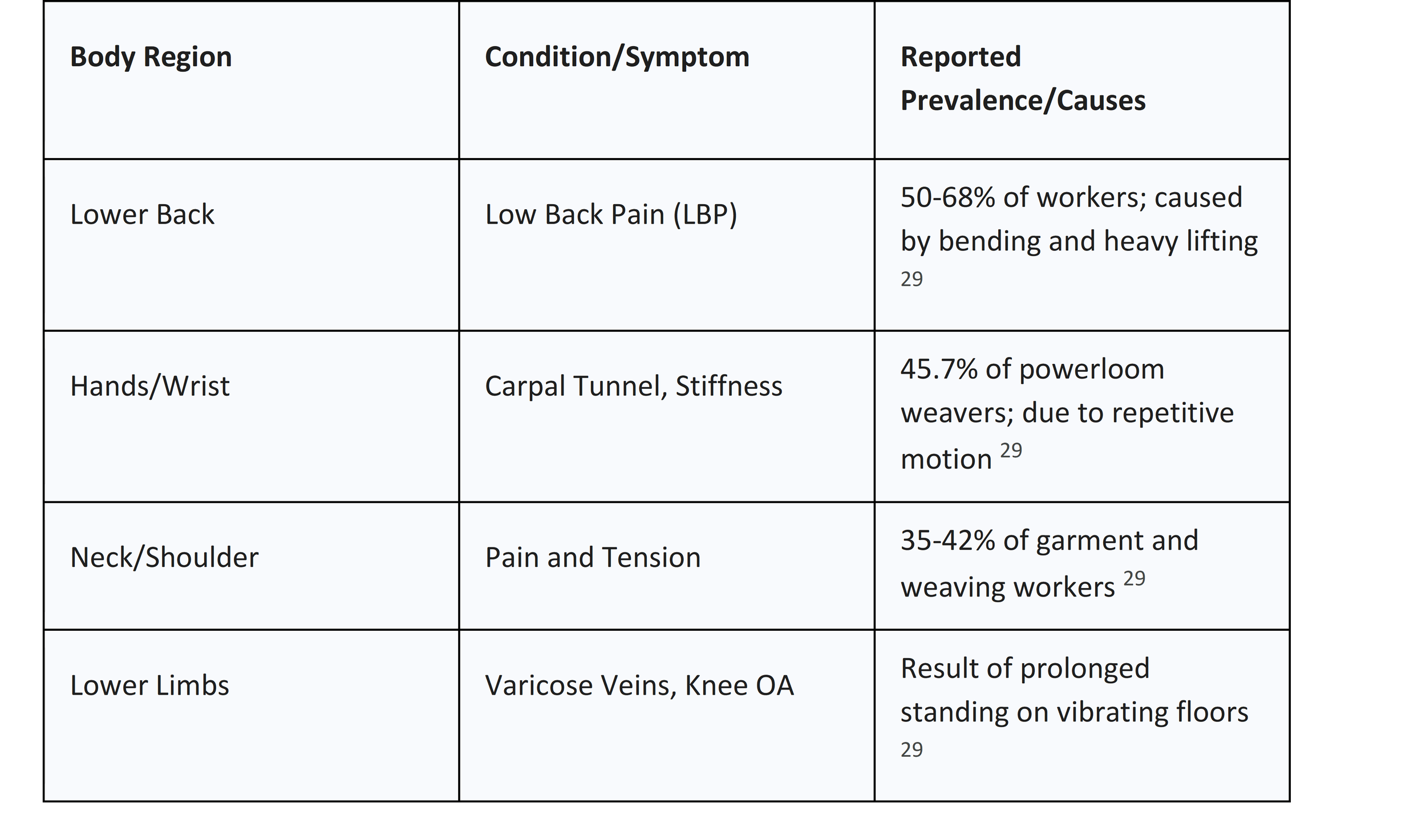

Ergonomic stressors are a major cause of chronic disability in the textile sector, affecting workers across all segments.27

Postural Strain and Manual Material Handling

Workers are frequently subjected to prolonged standing or sitting in fixed, awkward postures for 8 to 12 hours a day.25

● Heavy Lifting: Manual handling of heavy cloth rolls and warp beams is a primary cause of low back pain and carpal tunnel syndrome.25

● Ergonomic Assessments: Research using RULA (Rapid Upper Limb Assessment) has identified high-risk levels in material shifting operations, where Lifting Index (LI) values often indicate a severe risk of injury.

Prevalence of MSDs by Segment

Studies in Indian cities reveal a consistent pattern of musculoskeletal suffering among textile workers.29

Biological Hazards and Microbial Ecology

Natural fibers like cotton, wool, and jute fibers create a habitat for microorganisms, which can act as pathogens for the workers.31

● Bacteria and Fungi: Genera found in air samples and on raw materials include Bacillus, Streptococcus, Aspergillus, and Penicillium.31

● Jute Retting Hazards: In the jute industry, the retting process often leads to the putrefaction of water, releasing hydrogen sulfide and causing deep wounds, eczema, and loss of toenails among workers who wade through the water.30

Psychosocial Hazards: Stress and Precarity

The mental health of textile workers is a vital dimension of well-being. The sector is characterized by high production targets, grueling shifts, and precarious employment.34

● Workplace Stress: A meta-analysis of garment workers revealed a 14% prevalence of work-related stress and a 6% prevalence of depression.

● Precarious Work Impact: Overtime work markedly increases the likelihood of fatigue (OR = 7.579) and respiratory symptoms like blood phlegm (OR = 11.285).36

Regulatory Framework and Reform: The OSH Code 2020

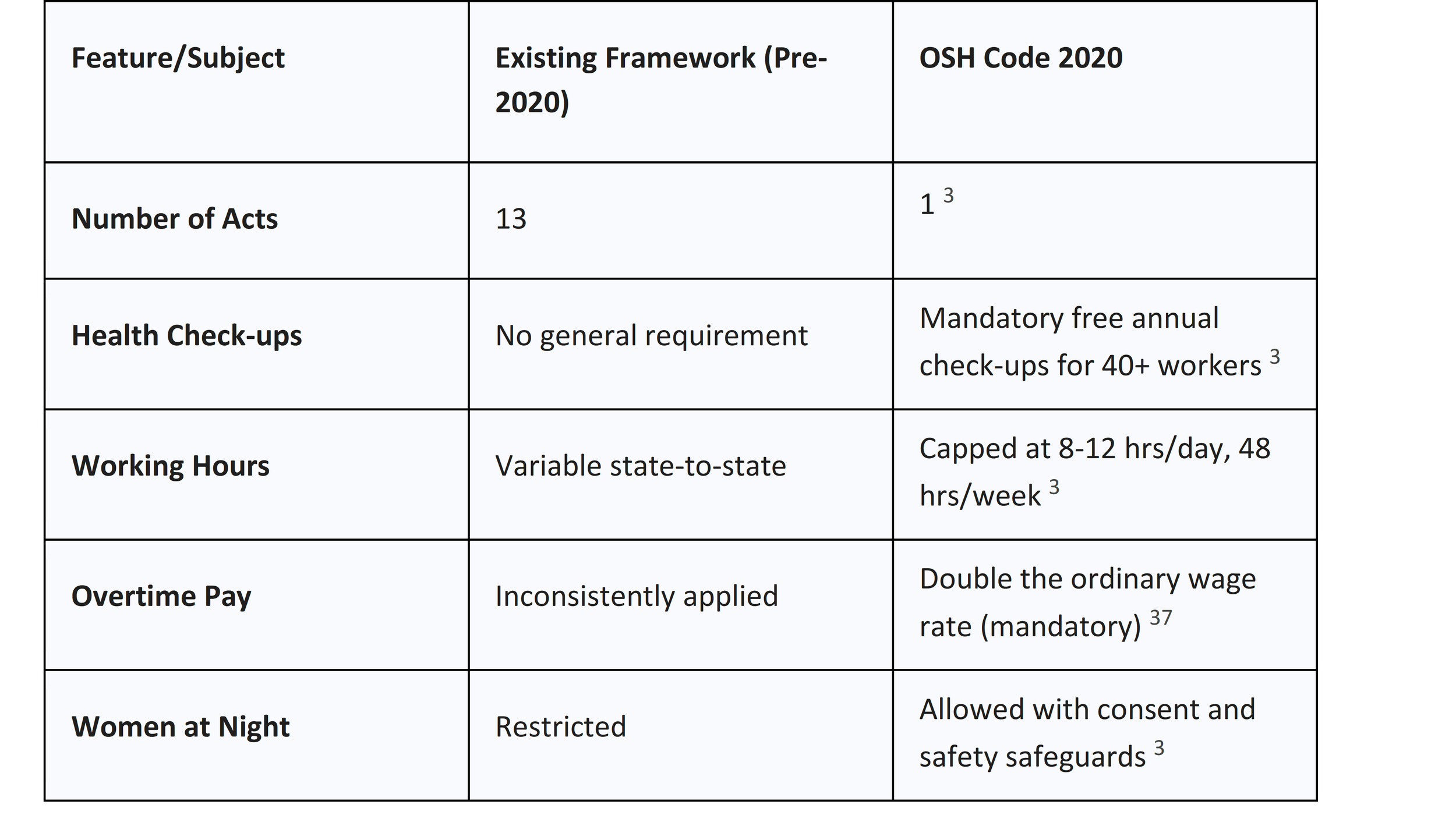

The recent implementation of the four unified Labour Codes—effective November 21, 2025—represents a paradigm shift in workplace regulation.37

Modernization under the OSH Code 2020

The OSH Code 2020 consolidated 13 central labor laws into a single framework.3

Statistical Insights into Occupational Health and Safety

Data from DGFASLI provide a quantitative window into the risks faced by the Indian workforce.

● Accident Statistics: While total injuries decreased from 28,164 in 2013 to 4,036 in 2022, fatalities have remained relatively steady, indicating a persistent risk of severe accidents.

● Inspection Trends: The number of hazardous factories inspected peaked in 2022 at 17,467, but the percentage of such factories inspected has fluctuated, dropping as low as 26% in 2021.40

Conclusions and Recommendations

The Indian textile industry represents a dual reality of immense economic potential and significant occupational vulnerability. Strategic success will depend on formalization, moving away from outdated machinery to reduce noise and dust, and improving the inspection-to-factory ratio.15 Rigorous implementation of the OSH Code 2020 is essential to ensure a sustainable future for the 45 million individuals who form the backbone of this sector.

References

1. Textile Manufacturing Industry in India - CII Blog, accessed January 11, 2026, https://ciiblog.in/textile-manufacturing-industry-in-india/

2. Occupational Risk Perception and Associated Factors Among Textile Workers: A Cross-Sectional Study From Türkiye - NIH, accessed January 11, 2026, https://pmc.ncbi.nlm.nih.gov/articles/PMC12301523/

3. How India's New OSH Code Reshapes Labor Compliance for Foreign Investors, accessed January 11, 2026, https://www.india-briefing.com/news/how-indias-new-osh-code-reshapes-labor-compliance-40915.html/

4. How India's New Labour Codes Are Reshaping the Textile Industry - Dinesh Exports, accessed January 11, 2026, https://dineshexports.com/new-labour-codes/

5. India's Textile Industry : Weaving the Future of Global manufacturing - Kirtane & Pandit Chartered Accountants, accessed January 11, 2026, https://www.kirtanepandit.com/pdf/1760524845.India's%20Textile%20Industry%20-%20Weaving%20the%20Future%20of%20Global%20Manufacturing.pdf

6. Textile Clusters in India, accessed January 11, 2026, https://www.textilesphere.com/2024/11/textile-clusters-in-india.html

7. INDIA'S TEXTILE INDUSTRY WEAVING A MODERN FUTURE - Vision IAS, accessed January 11, 2026, https://cdn.visionias.in/value_added_material/446f5-threads-of-transformation--indias-textile-industry-weaving-a-modern-future.pdf

8. India 2047: Vision and Strategic Roadmap for Technical Textiles - KPMG International, accessed January 11, 2026, https://assets.kpmg.com/content/dam/kpmg/in/pdf/2023/03/india-2047-vision-and-strategic-roadmap-for-technical-textiles.pdf

9. Labour Codes: Transforming India's Textile Sector with Simplified Compliance and Stronger Worker Welfare - PIB, accessed January 11, 2026, https://www.pib.gov.in/FactsheetDetails.aspx?id=150508&NoteId=150508&ModuleId=16®=1&lang=1

10. Byssinosis - Lung and Airway Disorders - Merck Manual Consumer Version, accessed January 11, 2026, https://www.merckmanuals.com/home/lung-and-airway-disorders/environmental-and-occupational-lung-diseases/byssinosis

11. Bysinosis: Occupational Lung Disease in The Textile Industry and Challenges in its Management | Eduvest - Journal of Universal Studies, accessed January 11, 2026, https://eduvest.greenvest.co.id/index.php/edv/article/view/43689

12. Byssinosis - StatPearls - NCBI Bookshelf, accessed January 11, 2026, https://www.ncbi.nlm.nih.gov/books/NBK519549/

13. Byssinosis - Wikipedia, accessed January 11, 2026, https://en.wikipedia.org/wiki/Byssinosis

14. Byssinosis : MedlinePlus Medical Encyclopedia, accessed January 11, 2026, https://medlineplus.gov/ency/article/001089.htm

15. Occupational Health in India - PMC - PubMed Central - NIH, accessed January 11, 2026, https://pmc.ncbi.nlm.nih.gov/articles/PMC6748231/

16. (PDF) Indian Textile Industry and Its Impact on the Environment and ..., accessed January 11, 2026, https://www.researchgate.net/publication/305774515_Indian_Textile_Industry_and_Its_Impact_on_the_Environment_and_Health

17. PEL for cotton dust when exposure is from cotton fibers used in the manufacture of absorbent glass tubes. | Occupational Safety and Health Administration - OSHA, accessed January 11, 2026, https://www.osha.gov/laws-regs/standardinterpretations/2012-01-18

18. OCCUPATIONAL HEALTH HAZARDS AND SAFETY ... - IJCRT.org, accessed January 11, 2026, https://www.ijcrt.org/papers/IJCRTAY02046.pdf

19. Chemical Safety in Textile Industry: 11 Smart Protocols for Long-Term Safety, accessed January 11, 2026, https://biopolchemicals.com/textile-chemicals/chemical-safety-in-textile-industry/

20. Occupational Hazards in the Textile Industry: What You Should Know, accessed January 11, 2026, https://gasdetection.com/articles/occupational-hazards-in-the-textile-industry-what-you-should-know/

21. India Updates Azo Dye Requirements for Imported Apparel and Textile Products - SGS, accessed January 11, 2026, https://www.sgs.com/en-be/news/2023/10/safeguards-12923-india-updates-azo-dye-requirements-for-imported-apparel-and-textile-products

22. (PDF) HEALTH AND SAFETY CHALLENGES IN THE TEXTILE INDUSTRY: A COMPREHENSIVE REVIEW - ResearchGate, accessed January 11, 2026, https://www.researchgate.net/publication/389575674_HEALTH_AND_SAFETY_CHALLENGES_IN_THE_TEXTILE_INDUSTRY_A_COMPREHENSIVE_REVIEW

23. Safety and Hazardous Atmosphere in Textile Industries - Online Clothing Study, accessed January 11, 2026, https://www.onlineclothingstudy.com/2013/07/safety-and-hazardous-atmosphere-in.html

24. Occupational health hazards in textiles industry - Hind- Research Journal, accessed January 11, 2026, http://researchjournal.co.in/upload/assignments/9_267-271.pdf

25. Occupational Health Hazards And Control Measures In ... - IJCRT.org, accessed January 11, 2026, https://www.ijcrt.org/papers/IJCRTAY02033.pdf

26. Workers Health and Safety in the Textile Industries in Delhi - European Economic Letters (EEL), accessed January 11, 2026, https://eelet.org.uk/index.php/journal/article/download/274/230

27. A systematic review of work-related health problems of factory workers in the textile and fashion industry - Oxford Academic, accessed January 11, 2026, https://academic.oup.com/joh/article/66/1/uiae007/7591975

28. Human Factor Analysis of Textile Industry Workers Using Various Ergonomic Assessment Tools - ResearchGate, accessed January 11, 2026, https://www.researchgate.net/publication/366904815_Human_Factor_Analysis_of_Textile_Industry_Workers_Using_Various_Ergonomic_Assessment_Tools

29. OCCUPATIONAL HEALTH PROBLEMS AMONG WORKERS OF TEXTILE INDUSTRIES IN KANNUR DISTRICT KERALA. - Worldwidejournals.com, accessed January 11, 2026, https://www.worldwidejournals.com/indian-journal-of-applied-research-(IJAR)/recent_issues_pdf/2021/November/occupational-health-problems-among-workers-of-textile-industries-in-kannur-district-kerala_November_2021_6675312343_1009450.pdf

30. Hazards in Jute Industry in India with special Reference to Jute Dermatitis. - Botanical Dermatology Database, accessed January 11, 2026, https://www.botanical-dermatology-database.info/pdfs/%233146ProcSocStudyIndustMed4~106~1952.pdf

31. Survivability of microorganisms on synthetic and semi-synthetic textile materials used in the production of special purpose clot, accessed January 11, 2026, https://www.aaem.pl/pdf-215225-133783?filename=Survivability-of-microorg.pdf

32. Biodeterioration of textiles - ResearchGate, accessed January 11, 2026, https://www.researchgate.net/publication/222314888_Biodeterioration_of_textiles

33. A review of pathogenic airborne fungi and bacteria: unveiling occurrence, sources, and profound human health implication - Frontiers, accessed January 11, 2026, https://www.frontiersin.org/journals/microbiology/articles/10.3389/fmicb.2024.1428415/full

34. Depression and Workplace Stress among the Garment Industry Workers: A Systematic Review and Meta-Analysis - NIH, accessed January 11, 2026, https://pmc.ncbi.nlm.nih.gov/articles/PMC12532156/

35. (PDF) Occupational Stress among Textile Industry Worker - ResearchGate, accessed January 11, 2026, https://www.researchgate.net/publication/360453863_Occupational_Stress_among_Textile_Industry_Worker

36. Precarious work and its impact on health: a study of female textile workers in Lahore and Faisalabad - ResearchGate, accessed January 11, 2026, https://www.researchgate.net/publication/390762846_Precarious_work_and_its_impact_on_health_a_study_of_female_textile_workers_in_Lahore_and_Faisalabad

37. Government Announces Implementation of Four Labour Codes to Simplify and Streamline Labour Laws, accessed January 11, 2026, https://labour.gov.in/sites/default/files/pib2192463.pdf

38. India – Government of India Issues Draft Rules on Four Labour Codes - KPMG International, accessed January 11, 2026, https://kpmg.com/xx/en/our-insights/gms-flash-alert/2026/flash-alert-2026-007.html

39. Labour Codes: Transforming India's Textile Sector with Simplified Compliance and Stronger Worker Welfare - PIB, accessed January 11, 2026, https://www.pib.gov.in/FactsheetDetails.aspx?Id=150508®=3&lang=2

40. इंडोशन्यूज़ INDOSHNEWS - DGFASLI, accessed January 11, 2026, https://dgfasli.gov.in/public/Admin/Cms/NewsLetter//68418a32bf8243.74803514.pdf